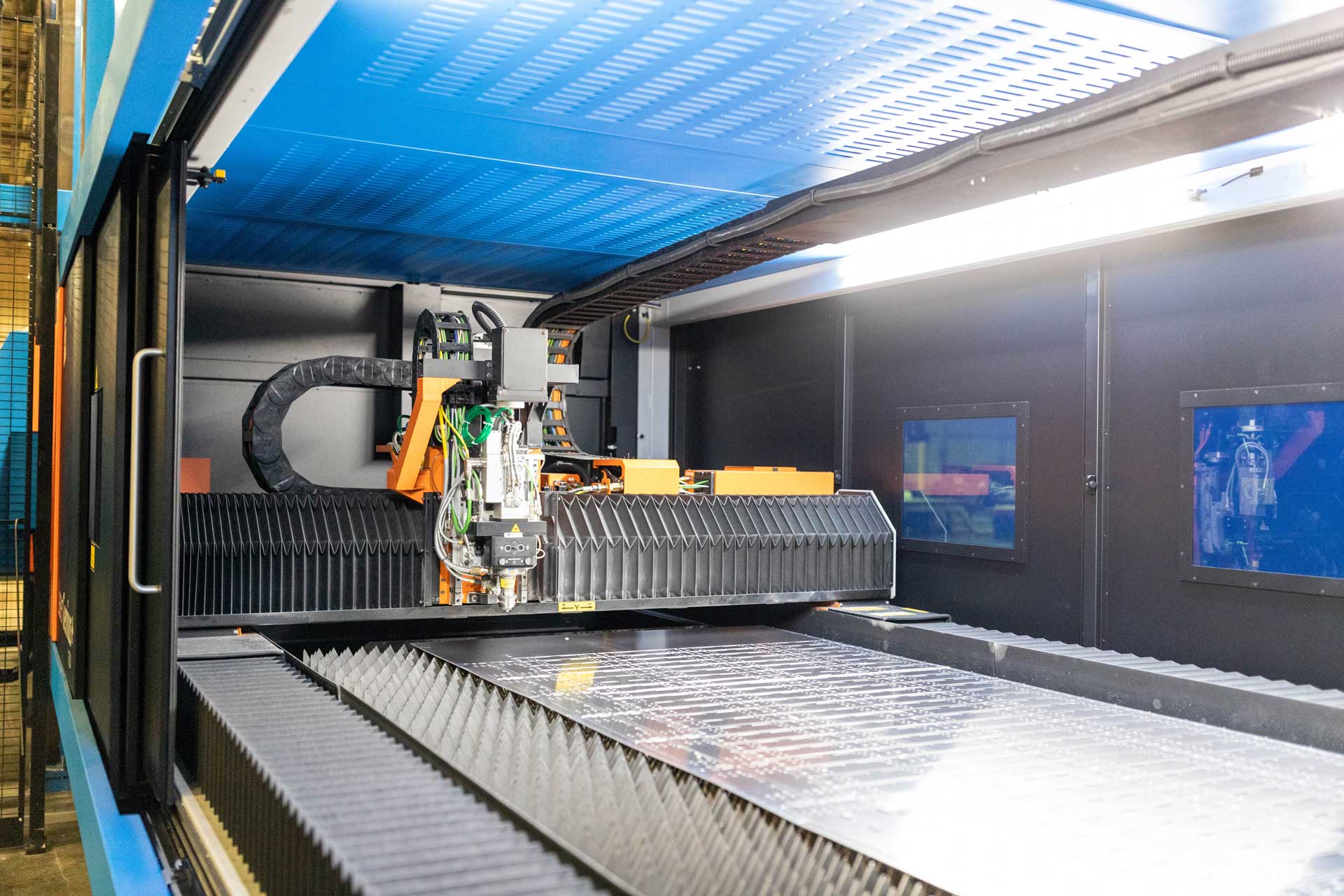

Custom Sheetmetal Fabrication

Are you looking for thin gauge metal? LGS Technologies can fabricate metal of all gauges and handle volumes small to large.

LGS Offers a wide variety of metals

LGS offers a wide variety of aluminums, from thin foils to thick plates.

Aluminum is known for superior corrosion resistance, formability, conductivity and high weldability. Aluminum is available in a variety of grades and used in various commercial and aerospace applications today.

1100 – This grade is commercially pure aluminum. It is soft and ductile and so it has excellent workability. It can be welded but it is not heat treatable. It has excellent resistance to corrosion.

2024 – One of the most commonly used high strength aluminum alloys. Commonly used where a good strength to weight ratio is required. Exhibits excellent fatigue resistance and can be formed in annealed condition and heat treated in secondary operations. Has lower corrosion resistance than other grades and is normally anodized in subsequent process to aid in this area.

3003 – Is the most widely used of all aluminum alloys. This grade is pure aluminum with added manganese to increase its strength (20% stronger than 1100 series). It has excellent corrosion resistance and workability. This grade can be drawn or spun, welded or brazed.

5052 – Has the highest strength alloy of the non-heat-treatable grades. Its fatigue strength is higher than most aluminums grades. This grade has excellent resistance to marine atmosphere and salt corrosion. It can be easily formed and has excellent workability.

6061 – Is the most versatile and widely used of the heat treatable grades. Is highly machinable and provides medium strength (lower than 2024 and 7075 when compared). Has great welding and brazing ability due to its high corrosion resistance.

7075 – is a high strength aluminum plate comparable to many steels. This grade is relatively higher costs compared to others.