Bonding 101: Pressure Sensitive Adhesive

Pressure sensitive adhesive (PSA) is a specific type of what most of us would call tape. Though, a PSA is any material (cloth, paper, metal, plastic, et.) that has a tacky adhesive on one or both sides as well as a release liner protecting the adhesive until it is used. PSAs are made in various formats and types and are typically sold in master roll form.

PSAs do not require water, heat, or solvent to activate, and they remain bonded or permanently attached at room temperature without changing phases (i.e., liquid to solid). Perhaps most importantly though, PSAs are the preferred choice of adhesive due to their ease of application with no drip or overspray and an easy clean up. PSAs easily bind to surfaces like foam, sponge, plastic, metal, or paper. These qualities, along with their affordability are why PSAs are being used at increasing rates by engineers, scientists, and consumers around the world.

Formats of Pressure Sensitive Adhesives

PSA are available in variety of formats with the three main formats being: Single Sided Tapes, Double Coated Adhesives, and Transfer Adhesives.

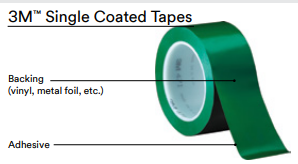

Single Sided Tapes are created by coating a carrier film on one side. These carriers can be most materials so long as they are flexible. Carrier films normally range in thickness from 1 to 10 mils and adhesive coatings normally ranging between 2 and 5 mils in thickness. Most single sided tapes are self-wound; however, they can be provided with a removable coated liner depending on the application. Most common tape products like electrical tape, masking tape, duct tape, etc. are sold in single side coated self-wound formats.

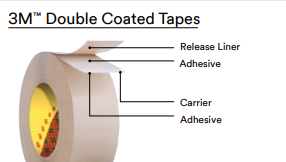

Double coated pressure sensitive adhesive consists of a carrier film that is coated on top and bottom. Like single sided tapes the carrier film can be any material as long as it is flexible; however, common films currently used are polyester, tissue paper and non-woven mesh. Double coated adhesives are normally self-wound on a release liner typically coated with a silicone release agent. Depending on the carrier film double coated PSA’s can provide additional dimensional stability for many bonding substrates.

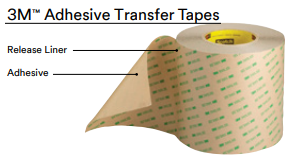

Transfer Adhesives are manufactured by direct coating a free film adhesive onto a coated release liner. This provides a thin free film of adhesive that can transferred easily to a variety of bonding substrates. Unlike some double coated PSAs, a transfer adhesive can provide flexibility and allow some bonding substrates to be manipulated more easily during assembly.

Types of PSAs

Rubber

Rubber adhesives offer a lower cost bonding solution and are typically used in indoor applications. Rubber adhesive generally are used at lower temperature ranges however rubber adhesives provide a great quick stick to most surfaces including low surface energy plastics. Rubber adhesives are commonly found in masking tape applications and can be formulated for clean removal.

Acrylic

Acrylic adhesives provide the broadest range of bonding applications because they can be formulated for specific applications. Acrylic adhesives are used both indoors and outdoors and typically have the ability to provide higher bond strengths for a wider range of temperatures. Acrylic adhesives are an excellent option for bonding to foam, sponge, metal, and many different plastics.

Silicone

Silicone adhesives are by far the most expensive and considered a specialty adhesive due to their ability to tolerate higher temperatures compared to Rubber and Acrylic adhesives. As a result, they are typically used in high heat applications and silicone adhesives are most effective when bonded with other silicone-based materials.

Are you ready?

We are here for you! Now that you know the basics of bonding and PSAs, give us a call today and let us help you with a selection of PSA for your application.

LGS Technologies

Providing custom cuts and precision sheet metal projects since 1953.

LGS offers a wide variety of custom fabricated services including custom die-cutting (steel rule and rotary), waterjet cutting, laser cutting, CNC routing, laminating, sawing, skiving, slitting, kitting, machining and sub- assemblies.