Introducing Our Newest Flexible Laser Die Cutting Solution

LGS Technologies is proud to announce their newest Edge Laser Technology.

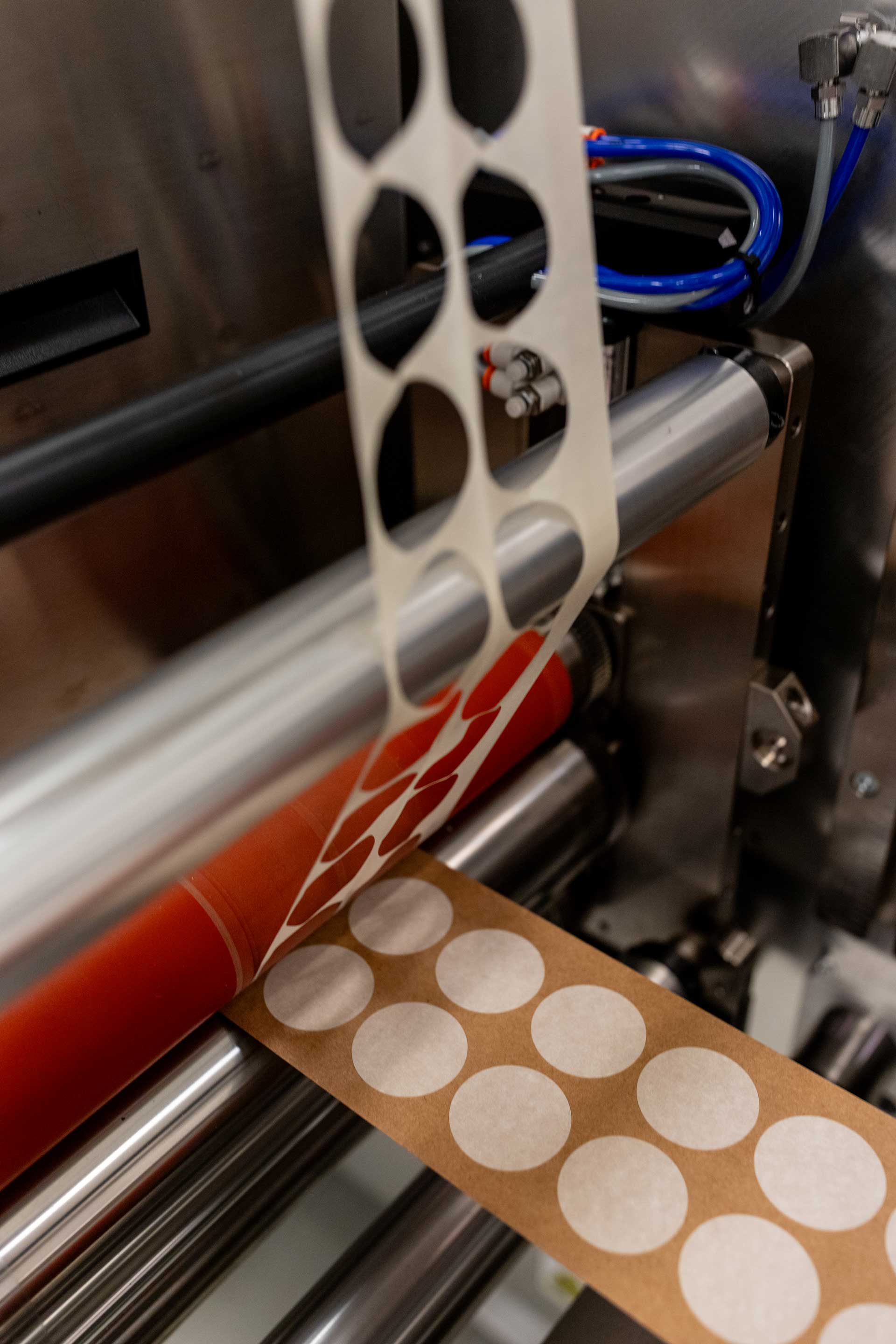

Our Delta Modtech Crusader 400W CO2 rotary press with laser integration offers roll to roll converting for a variety of materials, 7 stations, 8 spindles, and is 13 inches wide, with the capability to handle most rotary applications.

Our newest addition will allow increased capacity and provide new capabilities allowing our team to:

- Verify cut tests immediately

- Change cut profile or pattern on the fly

- No waiting on dies, no maintenance

- No wear on cutting tools – cut pattern and depth of cut stay consistent over time

- Easily cut small intricate sizes and shapes

- Laser cutting compliments jobs that require tight tolerance cutting, registration, and alignment

Our new Delta Crusader’s wide range of cut types and materials gives you the flexibility needed for almost any job type including:

Various Cut Types:

- Kiss cutting

- Through cuts and slug removal

- Perforation

- Slitting

- Scoring

Material Capabilities:

- PSA, polyester, paper, abrasives, cork, foam rubber, neoprene, silicone, PU, PE, PET polycarbonate, and polyethylene

- Thin foil and metal

- Abrasives, adhesives, fabric, paper, plastic, rubber, textiles

With years of experience behind us, we’re ready to create what you need! Ready to get started? Contact us to discuss your next project with our team of experts!

LGS Technologies

Providing custom cuts and precision sheet metal projects since 1953.