LGS Highlights Custom Skiving Featuring Armacell Foam

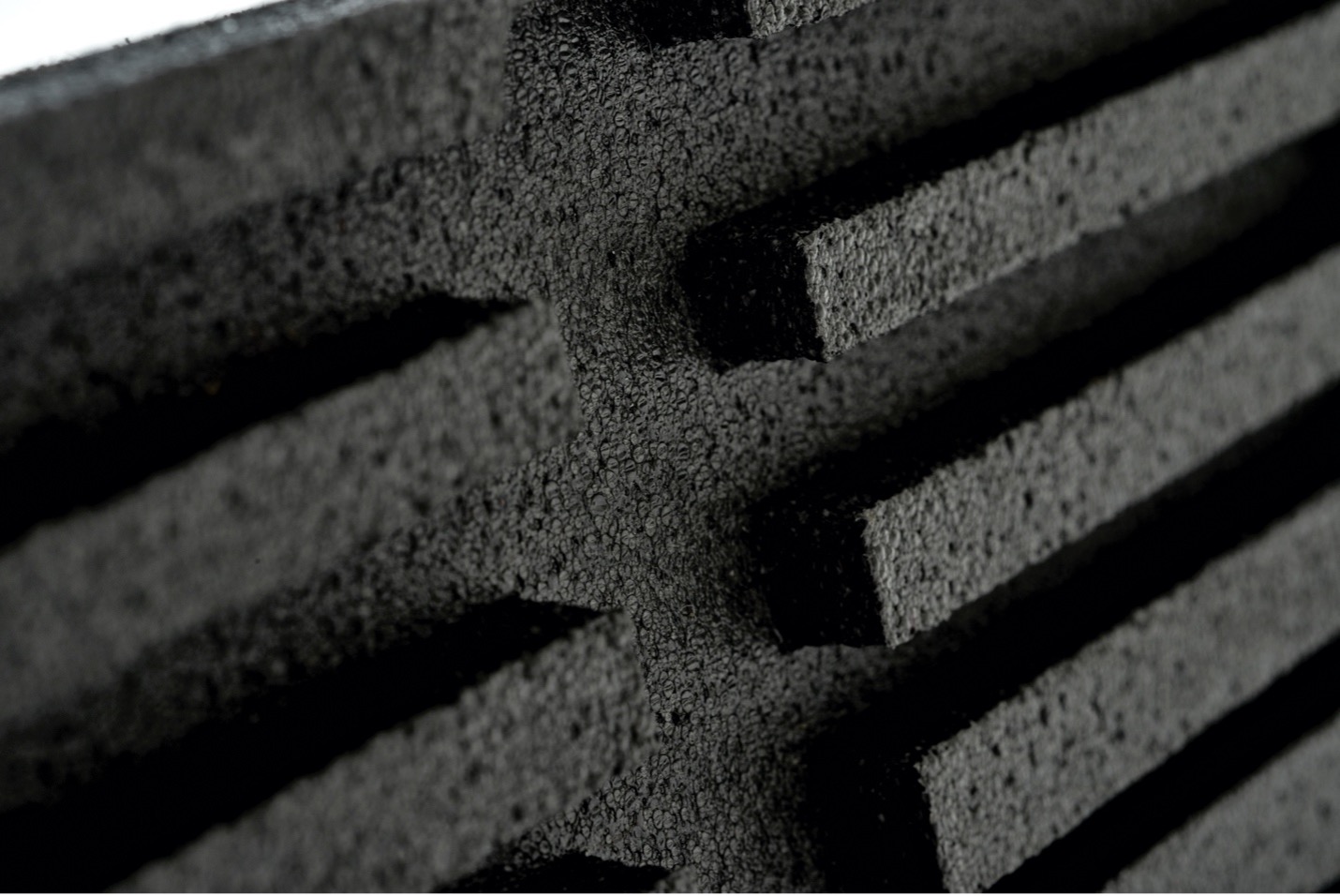

LGS Technologies is excited to highlight our Fecken-Kirfel loop skiver along with Armacell’s Monarch 5031 closed cell EPDM/Neoprene/Butyl blend foam in bun form.

As a leading provider of engineered foams, Armacell develops innovative foam products for thermal, acoustical, and mechanical applications. Armacell’s ArmaComp™ Monarch® 5031 foam and our F & K skiver allows LGS to offer custom thicknesses and quick turns to meet our customers’ specific requirements. Need die cut capabilities or PSA added? We can tailor our process to fit your individual needs.

Manufactured in buns, Monarch 5031 by Armacell is a widely used general purpose EPDM/Neoprene/Butyl blend, an industry standard.

Product Highlights:

- UL50E, UL508, and UL48 listed for gaskets and seals

- Listed on the approved source list of GMW 17408 Class I Type IV

- Incorporates flame retardants, meets the requirements of FMVss-302 at 2.5mm and higher and is listed with UL to UL 94 HF-1

- Meets all the physical property requirements of ASTM D 1056-14 2A1

- Monarch 5031 meets an extensive list of automotive and industrial specifications

For more information on Monarch 5031, click here to access our data sheet.

Loop Skiving with LGS

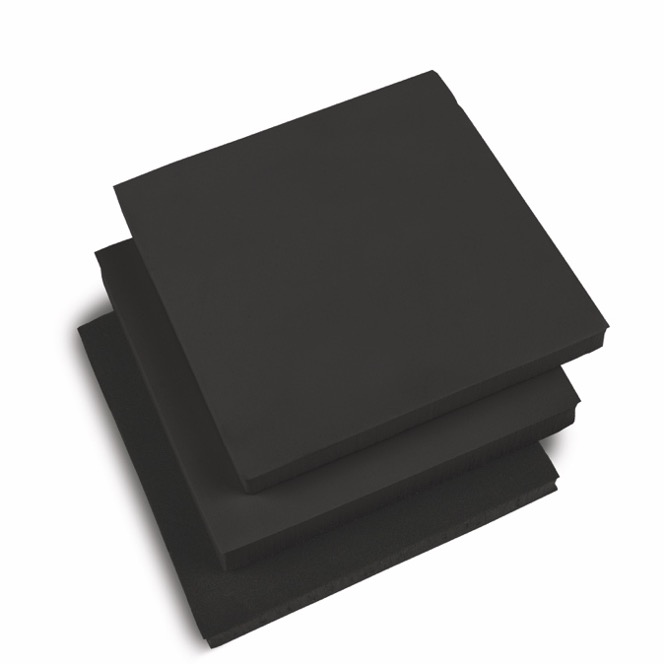

LGS can convert buns into sheets with a thickness of 1/32” to 2”. We can also bond buns end to end for a continuous roll form. This can be done with a variety of foam and sponge products in a variety of thicknesses.

LGS can quickly turn around orders with our in-house technology and wide inventory, so please call or email us today for a free estimate on your next sponge or foam project.

LGS Technologies

Providing custom cuts and precision sheet metal projects since 1953.

LGS offers a wide variety of custom fabricated services including custom die-cutting (steel rule and rotary), waterjet cutting, laser cutting, CNC routing, laminating, sawing, skiving, slitting, kitting, machining and sub- assemblies.